Introduction

In the world of computer vision and object detection, precision is key. Whether it’s for quality control in manufacturing, autonomous driving, or medical imaging, detecting objects accurately is the first step in automating real-world processes. But sometimes, the detection system might produce redundant or overlapping bounding boxes for the same object. This is where Non-Maximum Suppression (NMS) comes into play.

Non-Maximum Suppression is a crucial step in object detection pipelines, ensuring that only the most relevant detection results are kept, and irrelevant ones are discarded. In this blog, we will explore what NMS is, why it is essential for object detection, and how Akridata’s AI-powered visual inspection technology integrates this process to improve product quality detection in real-time.

What is Non-Maximum Suppression (NMS)?

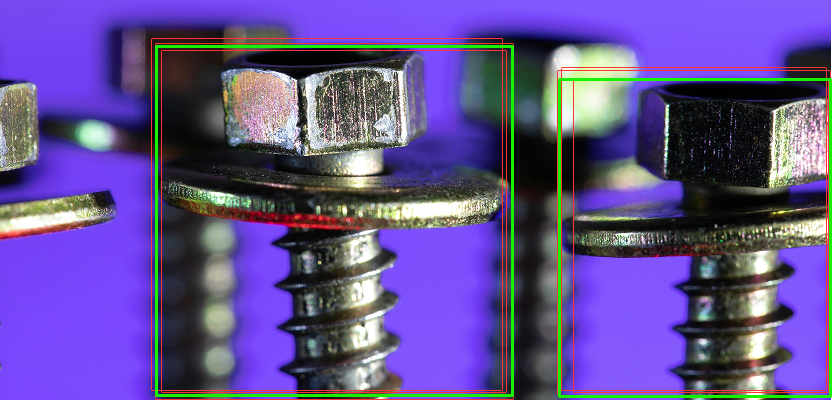

Non-Maximum Suppression (NMS) is an algorithm used to reduce the number of overlapping bounding boxes that are predicted for a given object during object detection. When a model detects an object, it may return several bounding boxes with slightly different locations and confidence scores.

The NMS process helps to filter out these redundant boxes by keeping the one with the highest confidence score and suppressing the others. In other words, it eliminates overlapping bounding boxes that represent the same object and ensures that only one box remains.

How Does Non-Maximum Suppression Work?

NMS follows a straightforward process:

- Sort: First, the algorithm sorts the bounding boxes based on their confidence scores (i.e., how confident the model is that an object is present).

- Pick the highest score: The bounding box with the highest score is selected as the reference for the object.

- Calculate overlap: The algorithm calculates the Intersection over Union (IoU) between the reference box and other boxes. IoU is a measure of overlap between two bounding boxes, and when the IoU exceeds a certain threshold, it indicates that the boxes refer to the same object.

- Suppress: Bounding boxes with an IoU higher than the threshold are suppressed, meaning they are removed from the final output, leaving only the box with the highest score.

- Repeat: The process is repeated for the next highest score, ensuring that all redundant boxes are suppressed.

Why is Non-Maximum Suppression Important?

Here’s why NMS is essential:

- Eliminates Redundancy: NMS removes redundant bounding boxes, ensuring that each object is detected once and only once, thus streamlining the results.

- Boosts Efficiency: NMS reduces the number of bounding boxes that need to be processed, leading to faster execution and more efficient systems.

- Optimizes Model Performance: Ensures that the model’s predictions are more interpretable and actionable, especially in real-time applications like Akridata’s visual inspection.

Integrating Non-Maximum Suppression into Akridata’s AI-Powered Visual Inspection System

At Akridata, object detection is a core part of our AI-powered visual inspection platform. In industries where product quality is paramount, accurate detection of defects can make a significant difference. Whether it’s identifying scratches, dents, or other manufacturing defects, our AI models work in real-time to ensure that only quality products make it to the end-user.

How Akridata’s NMS-Enhanced AI Inspection Benefits Your Business

The integration of Non-Maximum Suppression into Akridata’s object detection models significantly enhances our ability to detect defects with high precision. Here’s how our AI-powered inspection can benefit your business:

- Real-time Quality Control: Akridata provides real-time defect detection, enabling manufacturers to catch defects before they impact the quality of the final product.

- Cost Savings: By automating the defect detection process, businesses can reduce the need for manual inspections, leading to significant cost savings in labor and resources.

- Faster Time to Market: With quicker and more accurate defect detection, products can be inspected and released faster, improving production timelines.

- Enhanced Customer Satisfaction: Delivering defect-free products helps build customer trust and satisfaction, which is crucial for long-term business success.

Conclusion

Non-Maximum Suppression is an integral part of the object detection process, especially in applications like Akridata’s AI-powered visual inspection. By reducing redundant bounding boxes, NMS ensures that only the most relevant defect detections are considered, improving the accuracy, efficiency, and scalability of object detection systems.

Akridata’s AI models deliver real-time, automated defect detection that helps manufacturers maintain high product quality and streamline production.

No Responses