AI-Powered Visual Inspection.

Smarter, Faster, Accurate.

Trusted by leading AI and data science teams

AI That Works for You

Real-Time AI-Powered Insights

Multimodal Inputs & Usability

Seamless

Integration

End-to-End AI System Optimization

Akridata’s AI-Powered Inspection Suite

Three AI Solutions for Smarter Visual Inspection Automation

These solutions combine Al, automation, and deep learning to transform traditional and manual inspection processes.

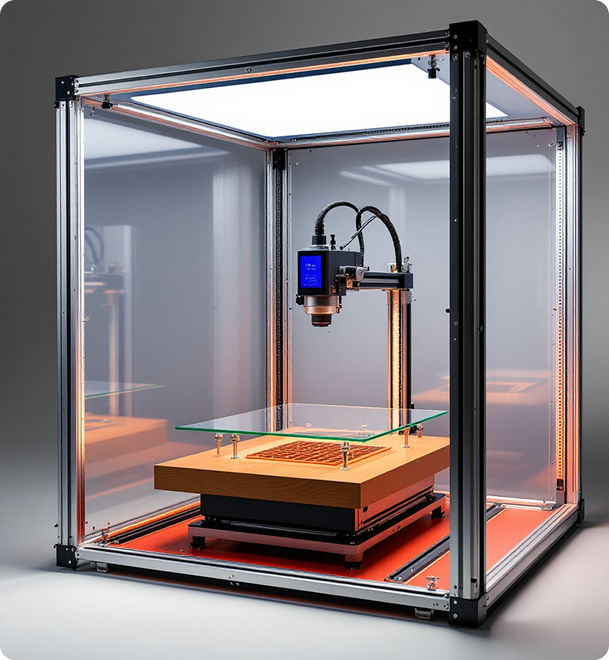

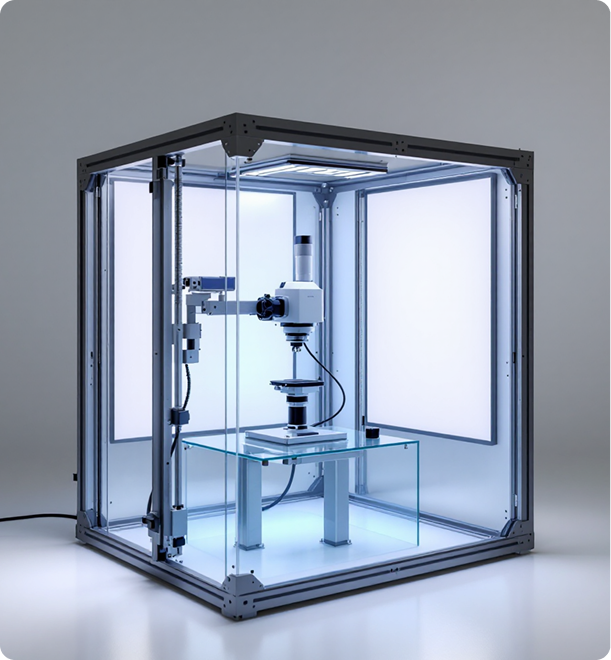

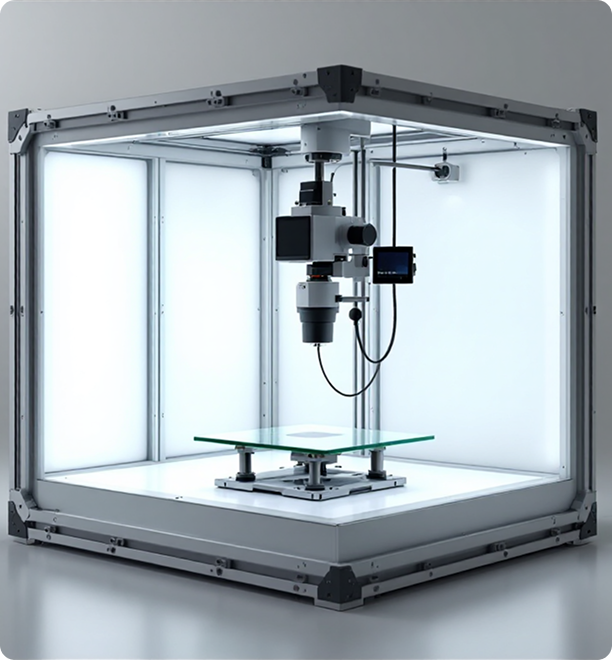

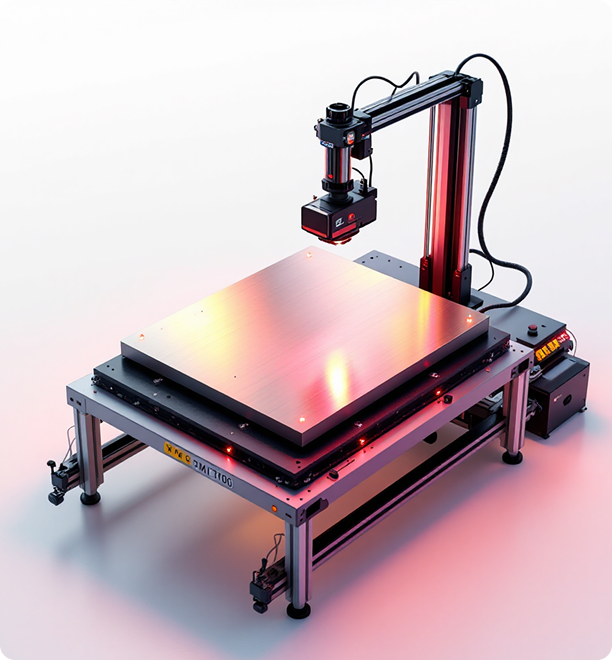

Vision Assist – AI-Assisted Human Inspection

A programmable image-capturing system that enhances manual quality control with automated defect detection and real-time analysis.

Automated 2 Axis Control Inspection

3 Axis Control for Manual Assembly and AI Assisted Inspection

Automated 2 Axis Control Inspection

Automated Inspection System with Camera

Large part Vertical Inspection System

Vision Command – AI-Driven Oversight for Manufacturing

A real-time AI-powered command center for defect detection, compliance tracking, and production optimization.

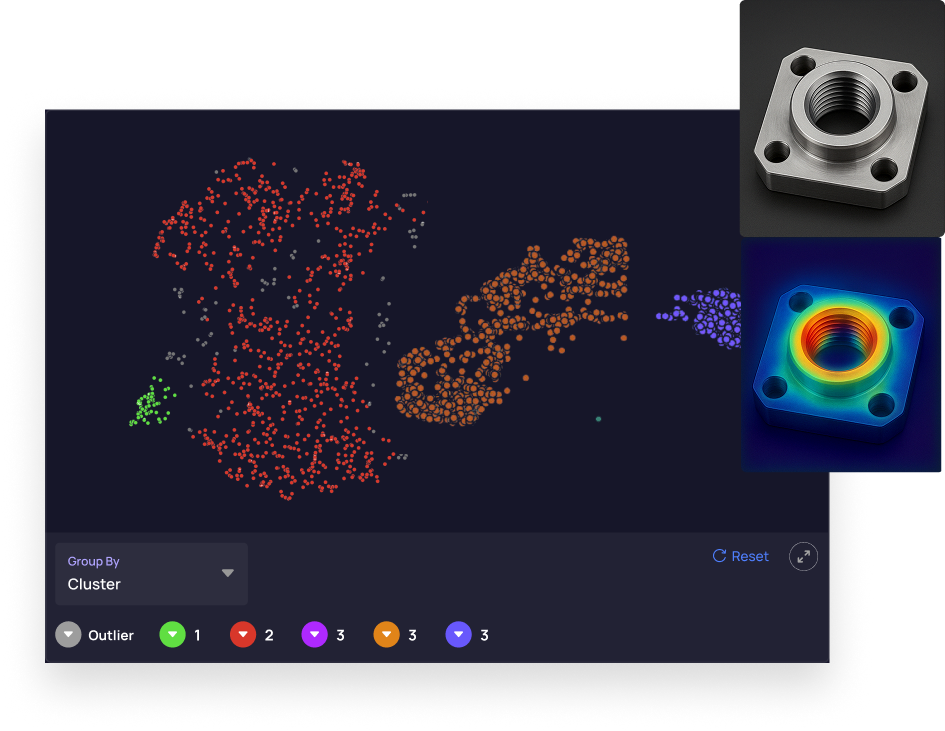

Vision Copilot – AI for Data Science & Model Development

An intelligent AI platform for building, refining, and deploying computer vision models with data curation, labeling, and analysis.

AI-Powered Quality Inspection Built for Your Industry

Smarter Defect Detection & Data Insights for Every Sector

Manufacturers & Production Teams

Automate inline and manual inspection to reduce defects and scrap rates while ensuring real-time quality control without disrupting production lines.

Explore Vision CommandQuality Control & Compliance Managers

Detect defects, anomalies, and inconsistencies before they impact customers while maintaining audit-ready inspection logs for compliance and regulatory requirements.

Explore Vision AssistAI & Machine Learning

Teams

Accelerate model development and training with automated data curation, labeling, and synthetic data generation, ensuring higher-performing AI models.

Explore Vision CopilotAutomation & Industrial Engineering Teams

Seamlessly integrate AI-powered inspection into production workflows, enhancing efficiency and defect detection while keeping operations running smoothly.

Explore Vision CommandVP of Quality

Improve product reliability, reduce defects, and optimize efficiency with AI-powered anomaly detection, ensuring higher yield and consistent quality at scale.

Data Scientists & AI Engineers

Curate, train, and refine computer vision data & models with advanced AI-driven tools for better accuracy, edge case identification, and real-world deployment.

Explore Vision CopilotAI-Powered Inspection & Visual Intelligence for Every Industry

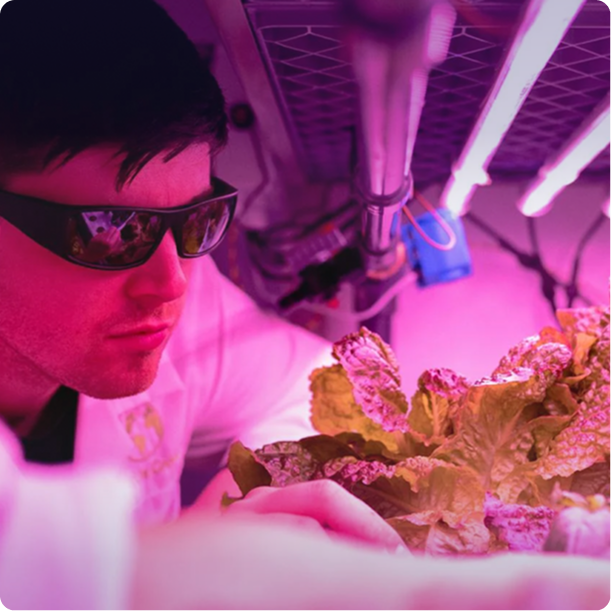

AI-Powered Food & Agriculture Inspection

Use AI-driven visual data analysis to detect crop diseases, optimize yields, and automate quality control, ensuring higher efficiency in agriculture and food production.

Explore Agriculture Solutions

Railway Safety & Maintenance, Powered by AI

Proactively detect cracks, wear, and structural weaknesses with AI-driven predictive maintenance, reducing downtime and improving railway safety.

Explore Railway Solutions

AI-Driven Automotive Quality Control

Ensure structural integrity, flawless assembly, and defect-free finishes with AI-driven inline and final inspection, enhancing safety, performance, and compliance for automotive manufacturing.

Explore Automotive Solutions

Medical Device Inspection Precision

Guarantee compliance, safety, and defect-free production with AI-enhanced inspection for medical devices, surgical instruments, and critical components.

Explore Medical Solutions

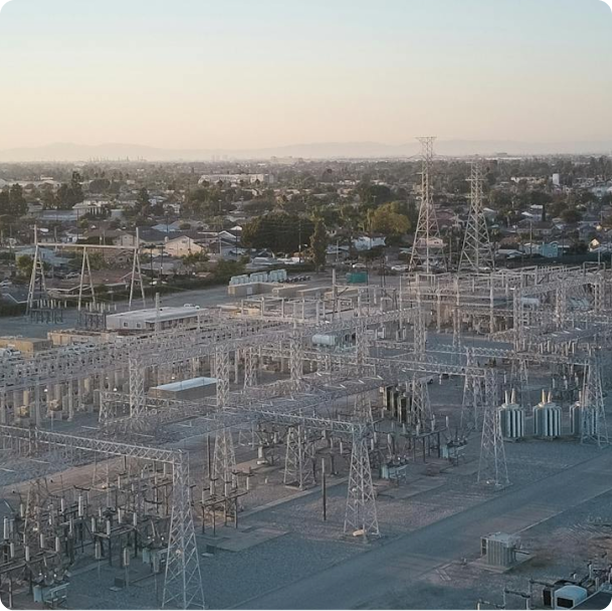

Critical Infrastructure Protection, Powered by AI

Safeguard essential systems like power grids, water supply, and communication networks with AI-driven monitoring and predictive analytics, reducing downtime and ensuring uninterrupted service for critical operations.

Explore Infrastructure Solutions

AI-Powered Manufacturing Excellence

Optimize production lines with intelligent quality inspection, predictive maintenance, and real-time performance analytics. Enhance efficiency, reduce defects, and ensure consistent product quality with AI-driven manufacturing solutions.

Explore Manufacturing SolutionsAI-Powered Inspection for Medical Devices: Ensuring Precision & Compliance

- 40% reduction in defect rates through real-time AI-powered visual inspection.

- Automated compliance tracking for stringent regulatory requirements.

- Improved consistency and accuracy, reducing reliance on manual inspection.

The company’s in-line inspection system, efficient but inaccurate, fell short despite repeated model tuning. Real-world production conditions and a rigid, speed-focused approach caused incorrect part flagging, posing a challenge in balancing speed without sacrificing accuracy or risking defective product shipments.

This medical device company implemented Akridata to boost accuracy and efficiency in assembly line inspections.

RESOURCES

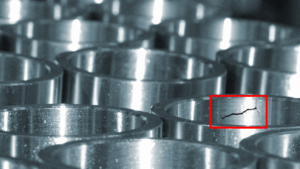

Surface Defect Detection with AI: Applications in Steel and Metal Industries

Surface defects are one of the most persistent challenges in steel and metal manufacturing. From scratches and dents to inclusions and cracks, even the smallest anomaly can compromise product quality, increase rework costs, and damage customer trust. Traditional inspection methods – whether human visual checks or legacy machine vision –

Sterilization as a Medical Device QA Blind Spot: How to Preserve Traceability Before, During, and After

QA visibility is critical at every stage of medical device manufacturing. Sterilization is no exception, yet it’s often the point where visibility is lost. And when visibility is lost, risk creeps in. Once a device is sealed for sterilization, it can disappear from inspection until the cycle ends. This blind

Visual Inspection as a Competitive Differentiator for Contract Manufacturers

When a medical device batch is rejected, the cost is staggering. A single rejection can wipe out $600K-$2M in logistics, rework, and re-sterilization costs. But the real damage goes far beyond mere dollars. Quality misses can cause strained Original Equipment Manufacturers (OEMs) and Contract Manufacturers (CMs) relationships, delay launches, and

FAQs

AI-powered visual inspection uses computer vision and machine learning algorithms to detect defects, anomalies, and quality issues in real time. Akridata’s platform processes multimodal inputs—such as images and videos—from production lines to identify deviations with high accuracy, reducing reliance on manual inspection.

Transform your AI Visual Inspection Process Today