Akridata Named a Vendor to Watch in the IDC MarketScape for Worldwide Data Labeling Software Learn More

Akridata Vision Command: Real-Time Data Quality & AI Compliance Monitoring

Akridata Vision Command empowers manufacturers with real-time data quality monitoring and AI-powered compliance oversight. From identifying defects instantly to automating compliance audit trails, Vision Command provides an intelligent layer of monitoring and decision support using vision AI technology.

problem

Inspection Oversight Challenges

Traditional inspection systems fall short in delivering real-time monitoring, leading to inefficiencies and regulatory gaps.

Disconnected Inspection Systems

- Manufacturers struggle with real-time defect detection, leading to high scrap rates and production inefficiencies.

- Lack of Centralized Visibility – Quality data lives in silos, limiting system-wide optimization and slowing issue resolution.

- Manual inspection processes slow down throughput and increase human error.

- Manual Compliance Tracking – Meeting strict regulatory standards requires precise, automated audit trails—yet most processes are manual and error-prone.

Traditional Control Dashboards

- Static & Hard to Customize – Legacy dashboards don’t adapt to evolving inspection workflows or modern factory setups.

- No AI Integration – Outdated systems lack feedback loops for continuous model improvement and real-time decision-making.

- Limited Scalability – Not built to manage real-time visual data across multiple lines, teams, or locations.

Super Charge your quality control: AI assists for Human Inspection

Solution

Akridata Vision Command: Real-Time Data Quality Monitoring at Scale

- AI-Powered Quality Control: Automates defect detection and reduces scrap rates

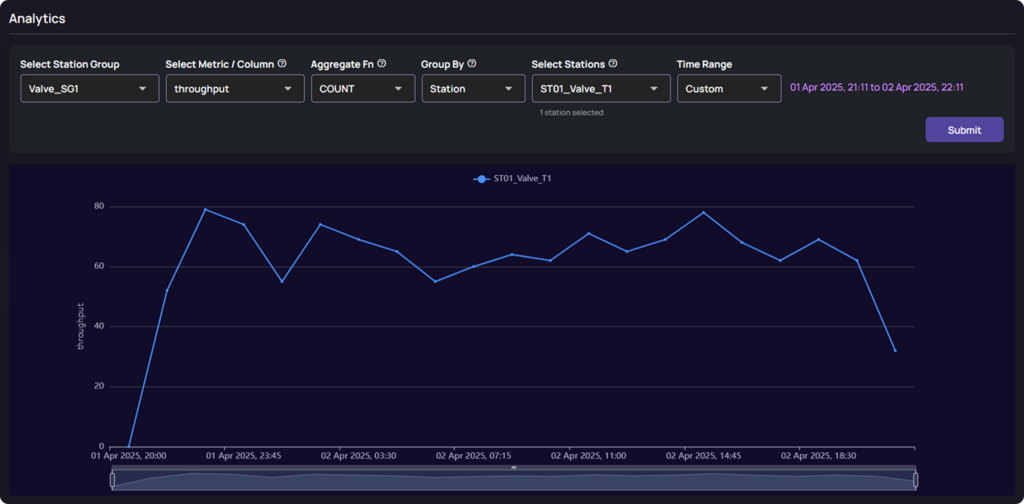

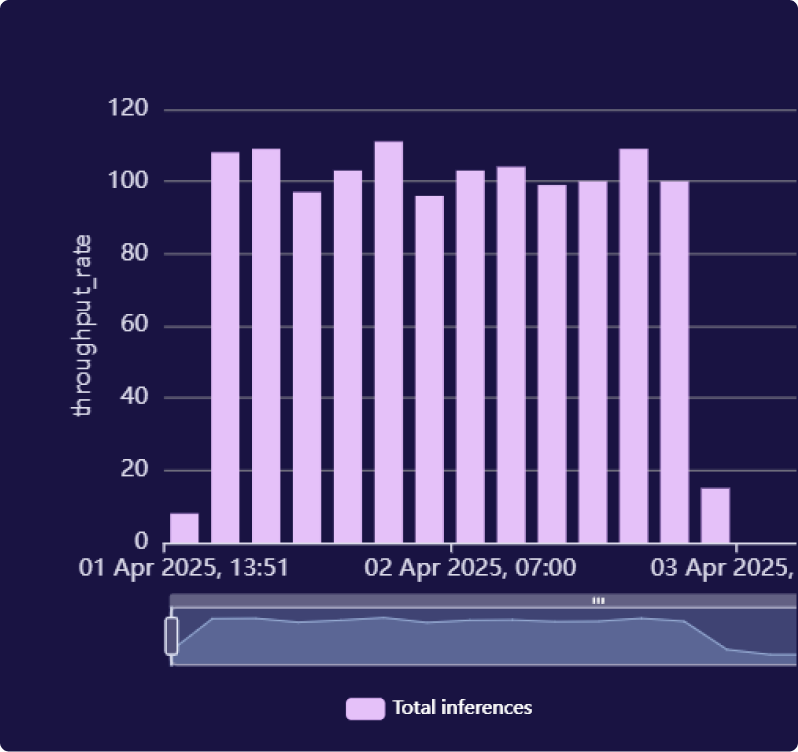

- Real-Time Production Monitoring: Gain instant insights into station-level performance

- Continuous Model Improvement: Retrain models with exception data to enhance accuracy.

AI-Powered Quality Control

(with real-time data analysis and monitoring capabilities)

Leverage real-time AI insights for continuous quality control and faster issue resolution.

Defect Trend Analysis

Spot recurring quality issues with built-in root cause analysis and interactive dashboards.

Automated Compliance Logging

(ensures AI-powered compliance monitoring and audit-readiness)

Seamlessly capture, store, and retrieve inspection data for audit-readiness and regulatory reporting.

Seamless Model Integration

Connect directly to Visual Copilot to deploy and refine AI models without interrupting operations.

Benefits of Vision Command

- Real-Time Defect Detection & Automated Alerts

- Real-time data quality monitoring with advanced Vision AI models

- AI-Powered Root Cause Analysis

- Automated compliance & audit logging using AI-powered monitoring

- Customizable Visual Overlays for Engineers & Operators

- Seamless AI Model Training & Continuous Improvement

FAQs

Vision Command by Akridata is an AI-driven quality inspection platform that offers real-time monitoring and compliance for precision manufacturing environments. It uses advanced computer vision and AI to identify defects, inconsistencies, and quality issues as they happen, ensuring higher product standards and reduced operational risk.

Ready for Real-Time Monitoring & Data Quality with Vision AI?