Akridata Named a Vendor to Watch in the IDC MarketScape for Worldwide Data Labeling Software Learn More

AI Visual Inspection System for Manufacturing Quality Control

Akridata Vision Assist is a next-gen AI-powered inspection system built for the manufacturing industry. With real-time computer vision AI, it enhances quality control, improves defect detection, and boosts throughput with automation-driven insights.

problem

The Inspection Challenges

Traditional manual inspection and conventional machine vision systems fall short in meeting the demands of modern AI-driven visual inspection for defect detection in manufacturing

Manual Inspection

- Subjective Assessments – Variability in human judgment impacts quality evaluations.

- Fatigue and Slow Throughput – Accuracy drops over time

- Costly and Hard to Scale – Labor-intensive and expensive

Traditional Machine Vision

- Fragile and High-Maintenance – Constant tuning needed

- Challenges in Detecting Subtle Defects – Prone to misclassification and oversight.

- Closed and Rigid Systems – Limited Flexibility

Super Charge your quality control: AI assists for Human Inspection

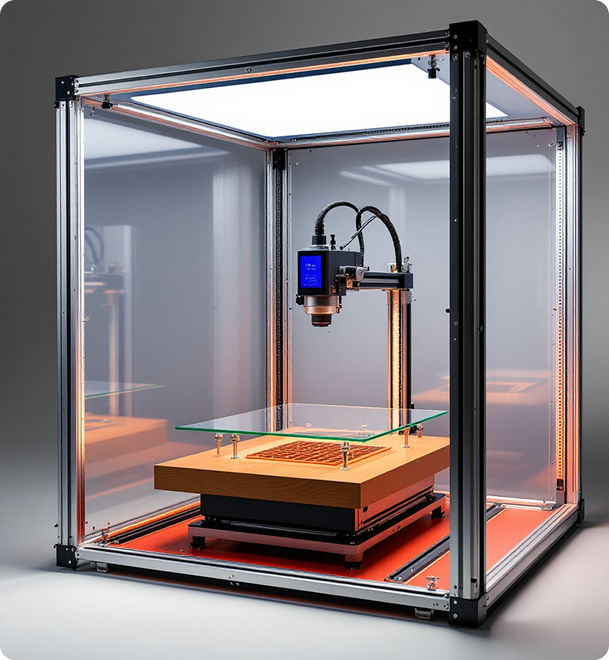

Automated 2 Axis Control Inspection

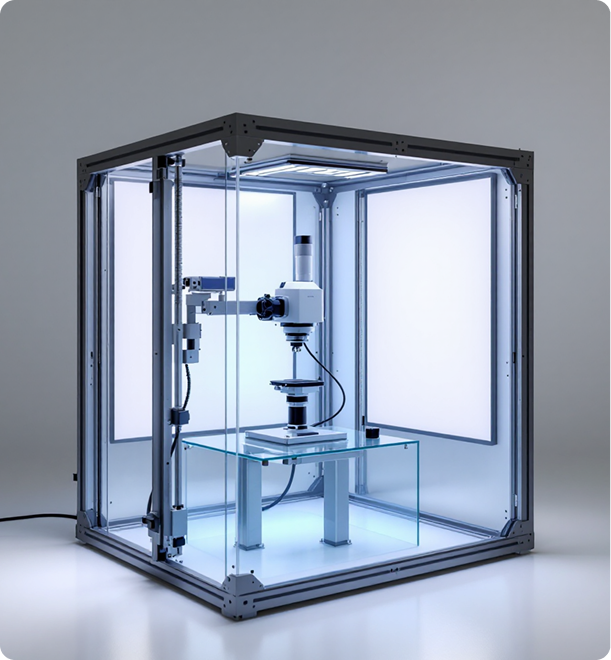

3 Axis Control for Manual Assembly and AI Assisted Inspection

Automated 2 Axis Control Inspection

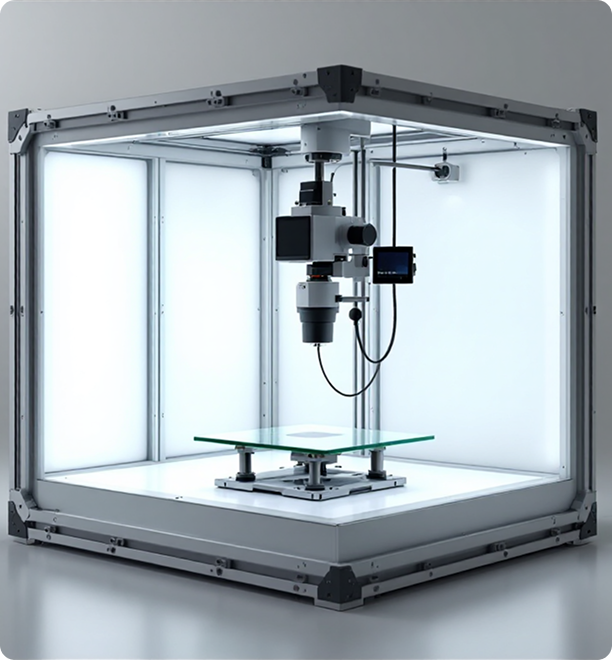

Automated Inspection System with Camera

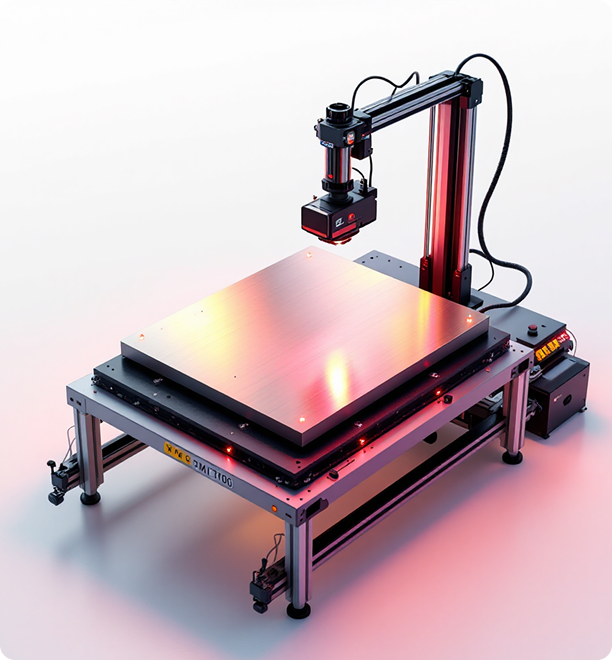

Large part Vertical Inspection System

Solution

Akridata Vision Assist

- Consistent & Accurate – AI powered precision

- Fast & Scalable – Handles high volume inspection

- Adaptive & Intelligent – Learns from new data

Real-Time Analytics

Monitor inspection metrics instantly.

Instant Performance Monitoring

Access real-time insights into inspection data.

Live Analytics

Track inspection metrics and performance instantly.

Immediate Inspection Feedback

Access real-time performance data.

Benefits of Akridata Vision Assist

- Reduce inspection errors by up to 90%

- Increase inspection throughput by 3x

- Lower operational costs with efficient resource allocation

- Improve product quality and customer satisfaction

- Enhance traceability with comprehensive data collection

- Powered by computer vision AI for manufacturing quality control and defect detection

FAQs

Vision Assist by Akridata is an AI-powered inspection system designed to revolutionize manual inspection processes in manufacturing. By using advanced computer vision AI for manufacturing, it enables faster, more accurate defect detection and quality control, reducing human error and improving production efficiency.

Ready to Modernize Your Manufacturing Quality Control with AI Visual Inspection?