Akridata Named a Vendor to Watch in the IDC MarketScape for Worldwide Data Labeling Software Learn More

Transform Manufacturing with AI-Driven Image Inspection

AI-Powered Manufacturing Solution

Achieve precision and efficiency in manufacturing processes with Akridata’s AI-powered visual data platform. Leverage cutting-edge technology for real-time defect detection, ensuring high-quality production and operational efficiency.

Why Choose Akridata for Manufacturing Solutions?

Manufacturers today face critical challenges such as:

- Increasing production volumes requiring faster quality checks.

- Manual inspection inefficiencies leading to defective products.

- High costs associated with product recalls and downtime.

Akridata solves these challenges by integrating AI-powered solutions that:

- Automate defect detection at scale.

- Improve inspection accuracy with deep learning.

- Reduce false positives and negatives in production lines.

Industries We Support

Akridata’s solutions are tailored for various industries, including:

Medical Devices

Enhance product safety and compliance.

Agriculture

Monitor produce quality in real time.

Automotive

Ensure structural integrity and defect-free assembly lines.

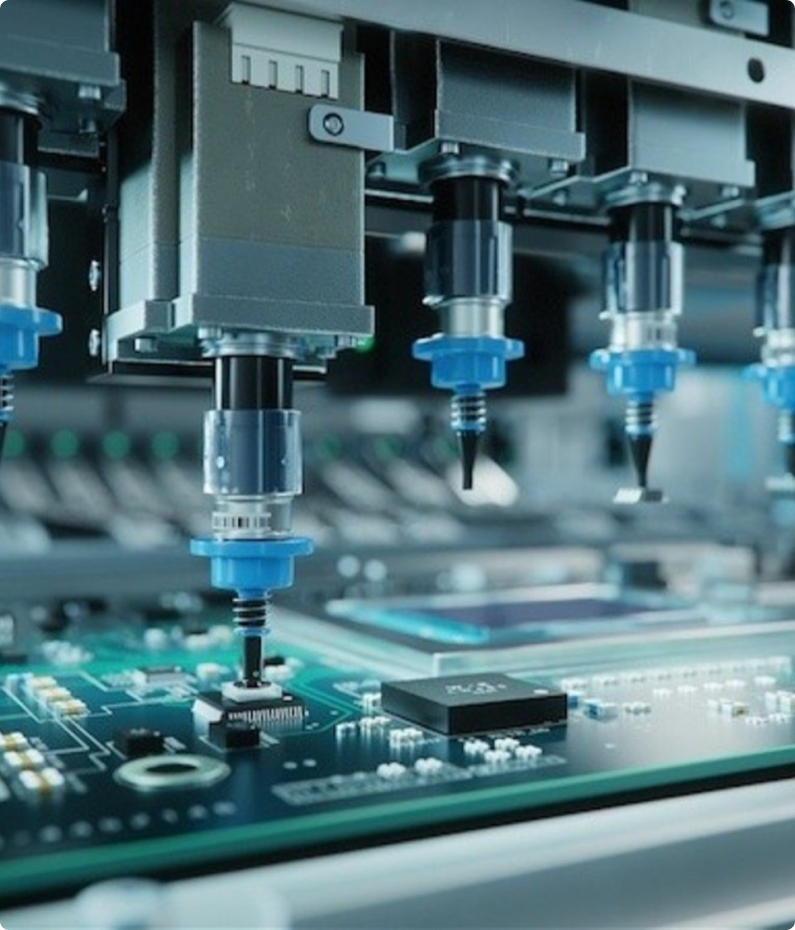

Electronics

Streamline high-volume inspections with precision.

How it Works: Minimize Defects with Akridata

Customize Feature Representation

Use Akridata’s Data Explorer to classify and analyze images captured by your vision systems. Tailored to your specific production environment.

Organize and Explore

Segment production data into distinct categories using clustering techniques, ensuring clear identification of pass/fail instances.

Surface Anomalies with Advanced Analytics

Detect and address production variations, reducing errors and enabling efficient troubleshooting.

Customer Success Story

Leading Electronics Manufacturer Increases Accuracy by 99%

By integrating Akridata’s solutions, a global electronics manufacturer achieved:

- 99% defect detection accuracy.

- Reduced false positives and operational inefficiencies.

- Enhanced production line efficiency without compromising speed.

FAQs

Akridata’s Vision Copilot uses deep learning to classify images captured by vision systems on manufacturing lines. It minimizes false positives and negatives, helping manufacturers identify defects more accurately, improving product quality, and reducing waste.

Akridata offers automated dataset curation, ensuring data diversity and optimizing model performance. Its intelligent tools help select high-quality data, improving the effectiveness of AI model training.

The solution utilizes advanced clustering and deep learning techniques to organize and classify visual data. By accurately distinguishing between “pass” and “fail” categories, it significantly reduces false positives, preventing unnecessary rework and ensuring only defective products are flagged.

Akridata’s solution is versatile and supports various industries, including medical devices, agriculture, automotive, and rail transportation, offering tailored image analysis to meet the specific quality inspection needs of each sector.

Manufacturers can expect a significant reduction in false positives (up to 40% as highlighted in customer success stories), improved product quality, fewer recalls, and lower operational costs, ultimately boosting overall efficiency.

Ready to Transform Your Manufacturing Process?

Don’t let inefficiencies slow down your production lines. Experience the power of AI with Akridata’s manufacturing solutions.

Products

- © 2025 Akridata

- Privacy Policy

- Terms & Conditions