Smarter Railway Inspections with AI-Powered Visual Analysis

Detect railway faults and prevent derailments with Akridata’s AI-driven inspection solutions

Prevent Derailments with AI-Based Railway Safety Solutions

SOLUTION

Enhancing Wheel Defect Detection with Artificial Intelligence

Problem

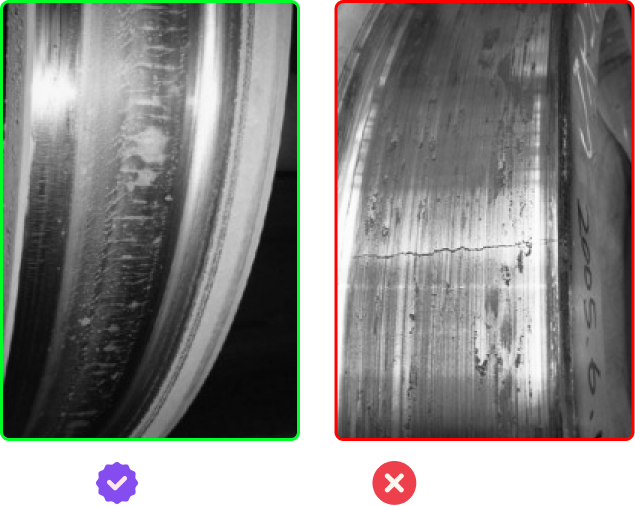

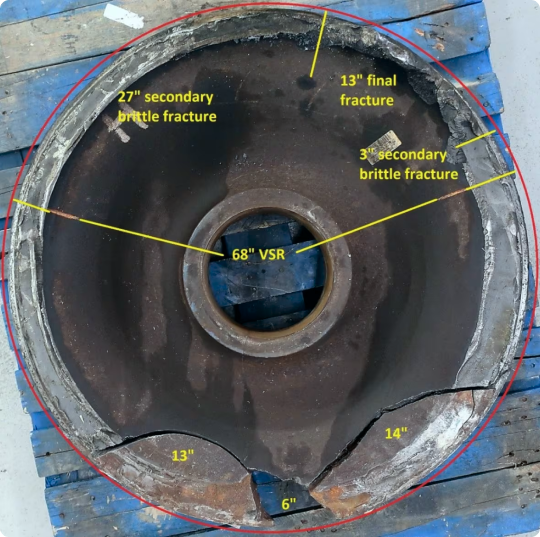

Railway operators capture millions of wheel inspection images, but with few samples of defects, their detection remains unreliable—posing serious safety risks.

Goal

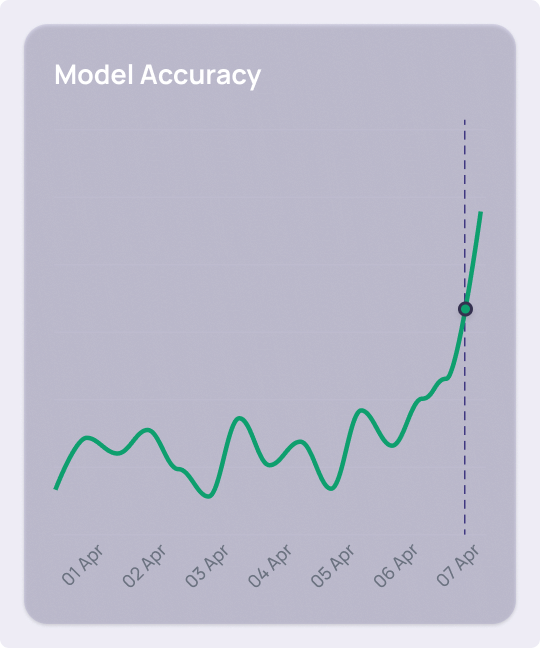

Leverage AI-driven analysis and synthetic data to improve detection accuracy, ensuring safer and more efficient rail operations.

Solution

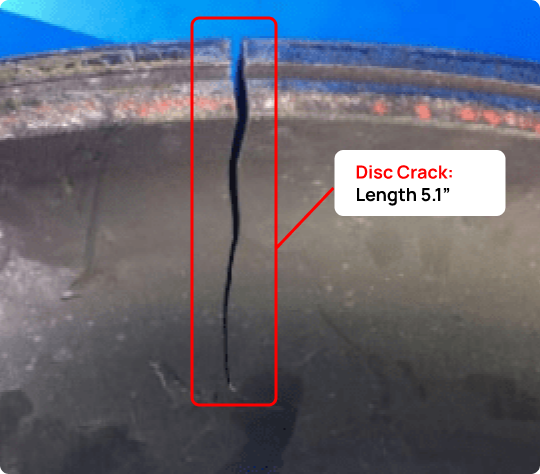

Leverage Akridata to generate quality synthetic images, enriching your dataset and enhancing your model's accuracy. Detect cracks, flat spots, and structural defects with greater precision—before failures occur.

See how Akridata can help.

AI-Powered Railway Inspection System: End-to-End Solution

Data collection and processing

Data Collection and Processing

Advanced Wheel and Track Inspection

Advanced Wheel and Track Inspection

Synthesizing Crack Variations

Synthesizing Crack Variations

Continuous Deployment and Monitoring

Continuous Deployment and Monitoring

Want to Build a Reliable Railway AI System?

Akridata Visual Data Platform

No in-house AI team? No problem. Akridata Edge is a plug-and-play solution for companies adopting AI in railways, providing highly accurate, ready-to-use models for inspection and railway AI system deployment.

Why Leading Railway Companies Choose Akridata

- Detect structural defects early with AI models

- Reduce derailment risks and unplanned downtime

- Integrate with existing railway infrastructure

How a Major Railway Company Achieved 98.5% Accuracy with AI in Railway

Akridata’s Vision Copilot was used to refine and enhance a large freight railway company’s inspection models. As a result, the company’s wheel inspection system reached 98.5% accuracy. Additionally, since using Akridata, they have not experienced any instances of real-world wheel cracks that went undetected by the inspection system.

FAQs

Ready to Modernize Railway Inspections with AI?