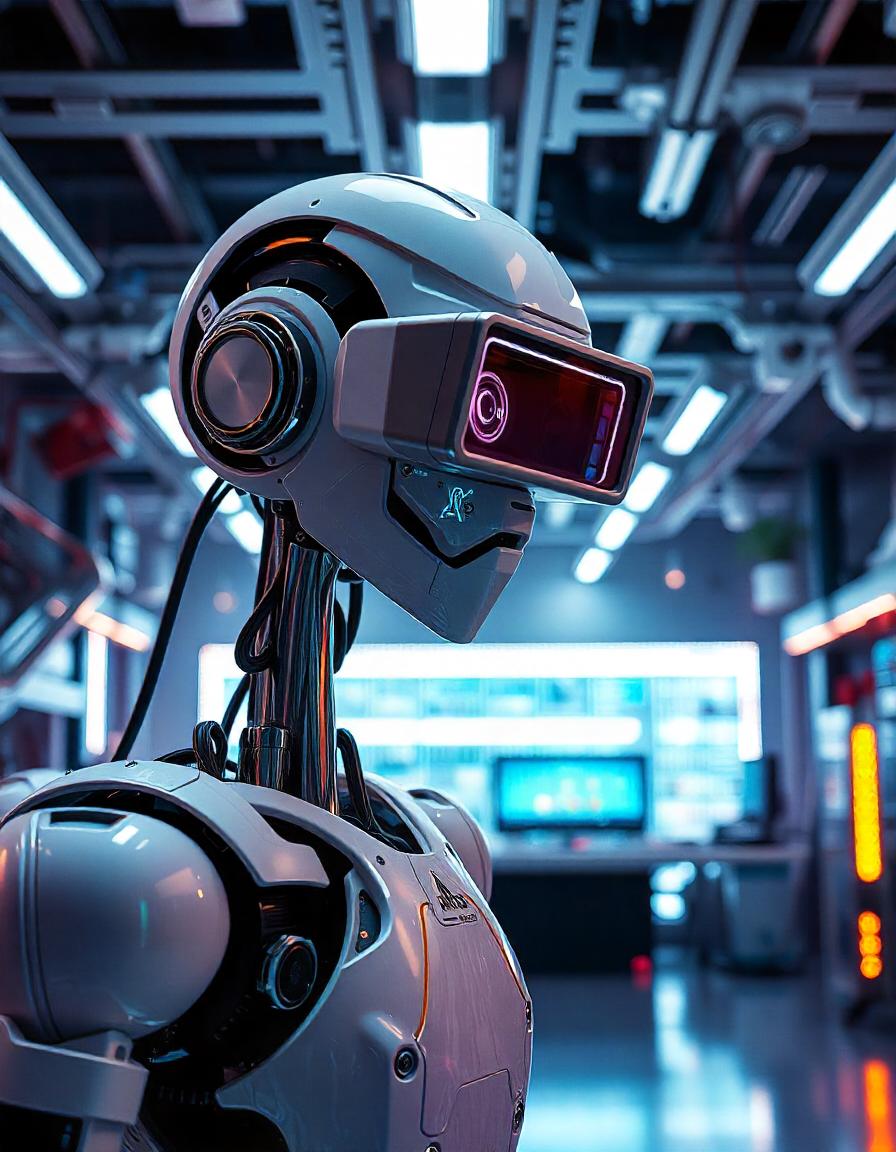

In recent years, the integration of machine vision systems in robotics has revolutionized industrial processes, automating tasks that once required human intervention. From manufacturing to asset monitoring, these systems have expanded the possibilities for robots, making them more efficient, precise, and capable. In this article, we’ll explore the fundamentals of machine vision in robotics, its applications, benefits, and the promising future it holds.

What Is a Machine Vision System in Robotics?

A machine vision system in robotics refers to the combination of hardware and software that enables robots to perceive, analyze, and interpret their surroundings. By leveraging cameras, sensors, and deep learning algorithms, machine vision systems empower robots to:

- Identify objects.

- Detect defects.

- Measure dimensions.

- Navigate environments.

This advanced technology mimics human visual perception but with greater precision and speed, making it a cornerstone of modern automation.

Key Components of Machine Vision Systems

- Cameras and Sensors

- High-resolution cameras and 3D sensors capture detailed images of objects and environments.

- Lighting

- Proper illumination ensures clear image capture, minimizing shadows and reflections.

- Processing Unit

- Advanced processors analyze visual data in real-time using algorithms.

- Software Algorithms

- Computer vision models powered by deep learning identify patterns, classify objects, and detect anomalies.

- Actuators

- Robots use actuators to respond to the visual information processed by the system, enabling movement and interaction.

Applications of Machine Vision in Robotics

Machine vision systems are transforming various industries by enhancing robotic capabilities. Below are some prominent applications:

- Manufacturing and Quality Control

- Automated defect detection in production lines ensures consistent product quality.

- Vision-guided robots assemble components with precision.

- Logistics and Warehousing

- Robots equipped with vision systems sort packages and manage inventory efficiently.

- Vision-guided drones inspect large warehouses for maintenance issues.

- Healthcare

- Robotic surgical systems utilize vision technology for unparalleled precision.

- Vision-based robots assist in diagnostics and medication management.

- Agriculture

- Robots equipped with machine vision systems monitor crop health and harvest produce with accuracy.

- Asset Monitoring

- Vision-enabled robots inspect equipment, infrastructure, and machinery, reducing downtime and maintenance costs.

- Retail and E-commerce

- Robots use vision systems to manage inventory, enhance customer experience, and optimize packaging processes.

Benefits of Machine Vision Systems in Robotics

- Enhanced Efficiency

- Robots perform tasks faster and with consistent accuracy, boosting productivity.

- Improved Quality

- Vision systems minimize human error, ensuring high-quality output.

- Cost Reduction

- Automated inspection and monitoring reduce labor costs and operational downtime.

- Safety Improvements

- Vision-guided robots handle hazardous tasks, protecting human workers from risks.

- Scalability

- Machine vision systems can be tailored to meet the specific needs of different industries.

- Data-driven Insights

- Real-time data collected by vision systems enables predictive maintenance and process optimization.

Challenges in Implementing Machine Vision Systems

While machine vision technology is highly beneficial, its implementation comes with challenges:

- High Initial Costs: Procuring and setting up machine vision systems can be expensive.

- Complexity: Integration requires expertise in robotics, software, and hardware.

- Data Processing Demands: Vision systems generate large volumes of data, necessitating robust processing capabilities.

- Lighting Variability: Inconsistent lighting conditions can affect system accuracy.

- Adaptability: Training vision systems to work in diverse environments can be time-consuming.

How Akridata Optimizes Machine Vision Systems in Robotics

Akridata leverages advanced deep learning and computer vision models to optimize machine vision systems for robots. By applying cutting-edge AI techniques, Akridata’s solutions ensure:

- Superior image analysis for defect detection and inspection.

- Real-time processing for swift decision-making.

- Scalability for diverse applications, from manufacturing to asset monitoring.

- Integration with cloud and edge computing for seamless operations.

Akridata’s technology stands out for its ability to handle vast datasets efficiently, ensuring that businesses achieve both speed and accuracy in their robotic operations.

Emerging Trends in Machine Vision Systems

The future of machine vision in robotics is promising, with advancements on the horizon:

- Edge AI Integration

- Machine vision systems will increasingly utilize edge computing for faster processing and reduced latency.

- Adaptive Vision Systems

- Robots will be equipped with self-learning capabilities to adapt to changing environments and tasks.

- Multi-modal Sensing

- Combining vision with other sensory inputs like thermal imaging and LiDAR for comprehensive perception.

- Miniaturization of Hardware

- Smaller, more powerful cameras and sensors will make vision systems more versatile and accessible.

- Sustainability Focus

- Vision systems will contribute to eco-friendly manufacturing and reduced energy consumption.

Real-world Examples of Machine Vision in Action

- Automotive Industry

- Vision systems guide robotic arms in assembling vehicles with unmatched precision.

- Automated quality checks detect minute flaws in vehicle components.

- Electronics Manufacturing

- Robots inspect circuit boards for defects, ensuring high-quality electronic products.

- Food Processing

- Machine vision identifies contaminants and ensures proper packaging in food production lines.

- Energy Sector

- Vision-enabled robots inspect wind turbines and solar panels, improving maintenance efficiency.

Conclusion

The integration of machine vision systems in robotics is transforming how industries operate, delivering unparalleled precision and efficiency. By bridging the gap between perception and action, these systems are paving the way for a smarter, automated future. Companies like Akridata are at the forefront, ensuring that machine vision technology reaches its full potential in optimizing robotic applications.

Embrace the possibilities of machine vision in robotics and unlock the next level of innovation for your industry.

No Responses