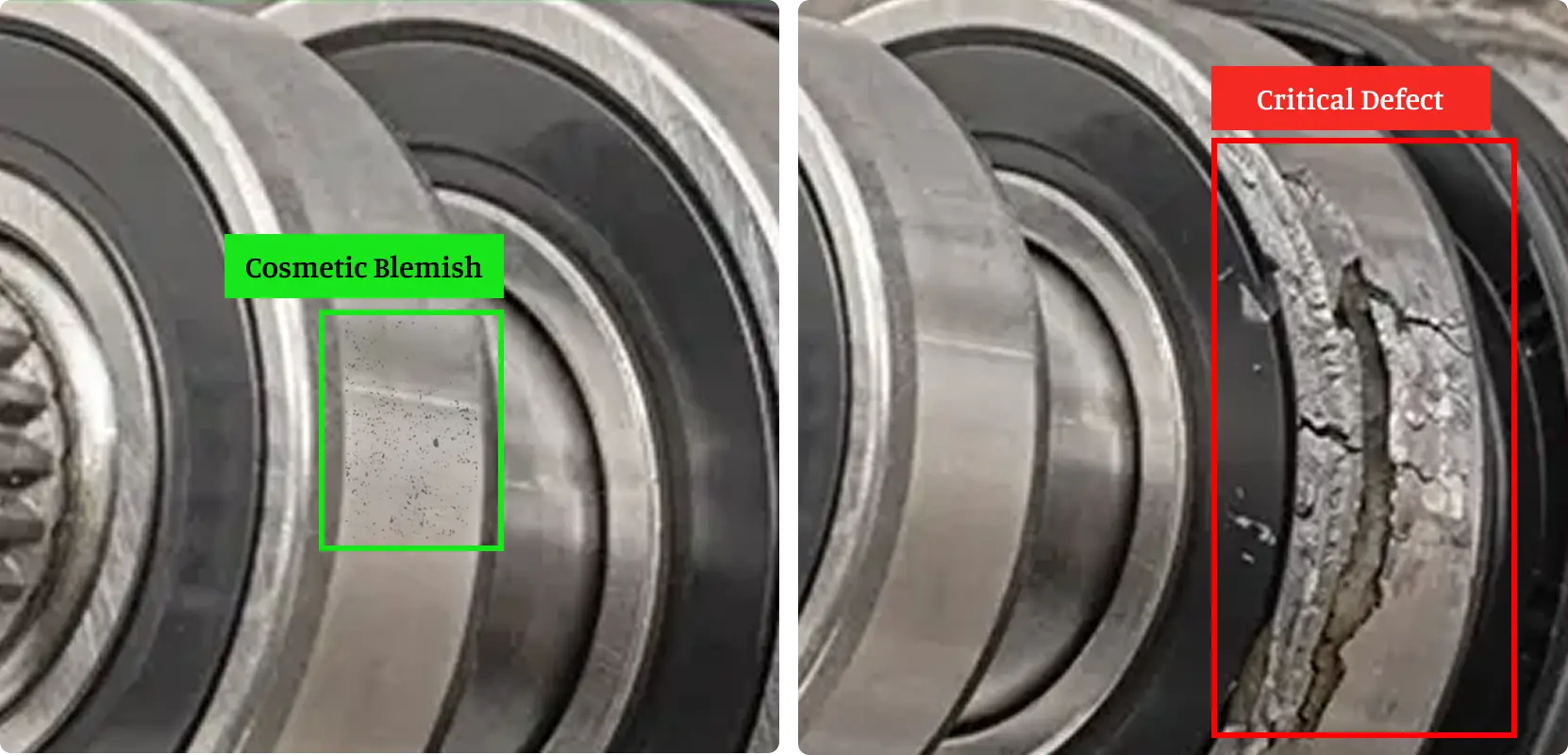

In modern manufacturing, not all defects are created equal – but they are often treated as if they are. A minor blemish on a surface finish might be completely inconsequential to a product’s function or safety, yet it could still trigger batch rejections, customer complaints, or costly rework. On the other hand, a seemingly trivial flaw might conceal a deeper structural issue that compromises performance or compliance.

The challenge? Telling the difference – consistently, accurately, and at scale.

This distinction between cosmetic blemishes and critical defects is not just a matter of visual inspection. It’s a question of business continuity, regulatory compliance, and customer trust. And for Original Equipment Manufacturers (OEMs) and Contract Manufacturers (CMs), getting it wrong has real consequences: missed delivery timelines, strained relationships, and long-term reputational damage.

With AI-powered visual inspection, manufacturers now have a way to address this challenge head-on – applying intelligence at the point of inspection to ensure the right calls are made every time.

When a Small Flaw Becomes a Big Problem

On the surface, a blemish may look like a minor issue – a small pit, discoloration, or surface roughness. But when quality control teams are under pressure to hit compliance metrics, meet deadlines, and reduce waste, these small decisions can snowball into bigger problems.

In many production environments, the default reaction is to reject any visual imperfection – regardless of whether it affects the product’s performance. This conservative approach is understandable but inefficient. It drives up scrap rates, increases rework cycles, and wastes valuable time. Worse, it creates misalignment between OEMs and their manufacturing partners, especially when QA expectations aren’t clearly defined.

The real cost? Not just the loss of a single unit, but the ripple effects:

- Unnecessary batch rejection

- Disrupted production schedules

- Excessive returns and replacements

- Erosion of trust in supplier relationships

And then there’s the inverse problem: overlooking flaws that actually matter. A microscopic crack in a medical implant or a misalignment in an automotive sensor may not be visible to the naked eye but can cause catastrophic failure. In these cases, the risk is not just financial – it’s regulatory, legal, and potentially life-threatening.

The Problem with Traditional Inspection Methods

Most visual inspection processes today rely on human inspectors or rule-based systems. Both come with limitations.

Human inspection is inherently subjective. What one inspector considers acceptable, another may flag as a defect. Fatigue, lighting conditions, and inconsistent training all contribute to variability. Even with detailed inspection checklists, human error remains one of the biggest challenges in quality control.

Rule-based machine vision systems, while faster and more consistent than humans, struggle with nuance. They operate on hard-coded thresholds – for example, flagging any blemish over a certain size. But in manufacturing, context matters. The same scratch may be critical on one component and harmless on another, depending on its location, depth, or the part’s end use.

Neither system is equipped to make judgment calls with the intelligence and context-awareness that’s needed in high-precision environments.

How AI Distinguishes Cosmetic Flaws from Critical Defects

AI-powered visual inspection changes the game by introducing real-time intelligence into the QA process. Instead of relying on fixed thresholds or subjective human calls, AI systems are trained on large datasets of real-world defects, learning to identify patterns, categorize flaws, and apply tolerance levels based on product context.

At Akridata, our AI-powered platform integrates deep learning with high-resolution imaging and multimodal inputs to deliver fast, accurate, and scalable inspection. Here’s how it works:

- Vision Assist captures ultra-clear images of each unit on the line, detecting both visible and near-invisible flaws.

- Vision Copilot allows teams to train models on what qualifies as “critical” vs. “cosmetic” for specific products, components, and materials.

- Vision Command enables centralized oversight across global facilities, ensuring consistent standards and rapid deployment of updated models.

By distinguishing between harmless blemishes and genuine defects, manufacturers can reduce false positives, cut down on unnecessary rework, and focus their resources on fixing real issues.

Use Case: Surface Imperfections in Consumer Electronics

In consumer electronics, appearance matters – but only to a point. A slight fingerprint or mark on an internal component may be irrelevant to function, but a smudge on a device’s screen cover could result in a return.

Akridata worked with a global electronics manufacturer to train AI models that could assess cosmetic flaws with product-specific tolerances. The models were trained to recognize scratch depth, reflection angle, and even the impact of ambient lighting during inspection.

The result: a 40% reduction in false defect flags and an 18% decrease in rework cycles – all without compromising end-user satisfaction.

Use Case: Cosmetic vs. Functional in Medical Devices

Medical device inspection presents a higher-stakes challenge. A blemish on an implanted device might be harmless, or it could signal contamination, a material inconsistency, or a sterilization issue. Making the right call is critical.

Using Akridata’s platform, a contract manufacturer for orthopedic implants trained AI models to detect and categorize common surface anomalies. Vision Copilot helped define nuanced defect categories – such as clinically irrelevant polish marks vs. material corrosion indicators.

More importantly, every decision was logged. Pass/fail outcomes, annotated images, model versions – all tracked in an immutable audit trail. This capability not only helped the CM reduce batch rejections but also ensured FDA-ready traceability.

Why This Matters for QA and Regulatory Compliance

The ability to differentiate between cosmetic and critical defects isn’t just operational – it’s regulatory. FDA, ISO, and other regulatory bodies require documentation on how inspection decisions are made. “Over-inspecting” is as much a problem as “under-inspecting,” especially when inspection logs lack context.

AI inspection systems like Akridata’s solve this by generating digital records for every unit inspected. These records include:

- Annotated images with defect classification

- Timestamped logs of inspection results

- Version control for AI models used

- Operator input, if applicable

This level of documentation simplifies audits, reduces compliance risk, and gives OEMs and CMs a common language for quality – built on data, not debate.

From Reactive QA to Intelligent Quality Management

What if quality wasn’t just a checkpoint – but a feedback loop? That’s the promise of AI-powered defect analysis. When inspection systems can learn, adapt, and feed insights back into design or production, manufacturers can:

- Identify recurring cosmetic issues and optimize processes

- Adjust manufacturing tolerances based on real-world defect data

- Correlate defect types with specific machines or shifts

- Predict when critical defects are likely to occur

By shifting from reaction to prediction, QA teams gain strategic value. They’re no longer just enforcing compliance – they’re actively improving product design, supplier performance, and operational efficiency.

Conclusion: Know the Difference, Protect the Product

Not every flaw is worth fixing. But knowing which ones are – and why – is the difference between a product that’s trusted and one that gets returned.

Cosmetic blemish or critical defect? With AI-powered inspection, you don’t have to guess. You get clarity, consistency, and confidence – at scale.

Akridata’s visual inspection platform empowers manufacturers to make smarter quality decisions, reduce waste, and create defensible records of every inspection. It’s already helping teams in medical devices, electronics, automotive, and industrial sectors make the shift to intelligent inspection.

In the end, it’s not about being perfect. It’s about being precise.

No Responses